Temperature and Humidity - How to handle ambient conditions

Like any digital textile printer, the Coloreel must operate within certain ambient conditions. Specifically, this means a relative humidity range of 30%–80% RH and a temperature below 28°C/82°F, see Technical data.

Note: The unit will turn itself off when operated outside the limits to prevent damage to the equipment.

Should this happen, here are some hints on how to solve the issue:

The best way to solve this is to operate within a room with climate control.

Use of portable humidifiers

-

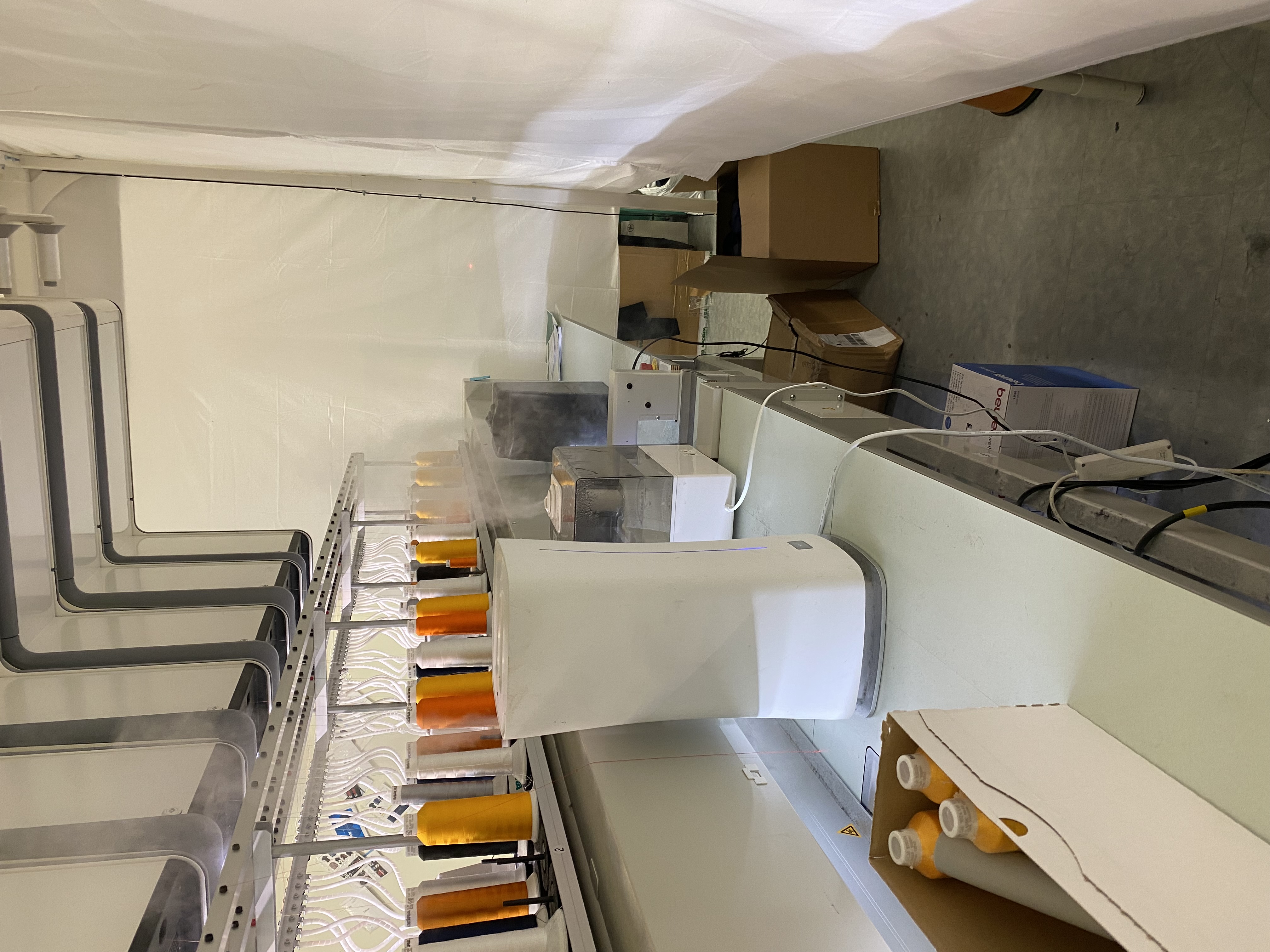

Several customers use portable humidifiers to create a local microclimate with higher humidity to solve the dry air issue.

Sometimes, a good solution is to use a humidifier in combination with various variants of plastic sheets or tent-like installations. In most cases, this works well, but we have a few instances where this has caused new problems due to excess water and condensation. Therefore, we issue these recommendations to avoid problems using a portable humidifier close to the Coloreel ITCU. lsakdgfjö

- We strongly recommend using an evaporative type of humidifier!

- If you use an ultrasonic humidifier, you must use distilled or deionized water. Do not use tap water! Regular water can give rise to white mist, which consists of mineral particles that may cause short circuits and destroy electronic equipment inside the unit.

Delimit the surrounding area.

-

- Suppose the ITCU is operated in large areas and areas with highly efficient ventilation. In that case, one idea is to create a more limited area (volume of controlled air) that will be easier and less expensive to manage.

- The best solution would be to create a "room in the room" with temperature- and humidity-control devices.

- The second best solution is to use a textile material to create a "tent" surrounding the ITCU to delimit the airflow and to add a humidifier to keep the humidity within specifications.

- WARNING! Be careful if using plastic material. Mind the higher risk of condensation.

- WARNING! Do not "wrap" the ITCU. There must be room for air circulation to prevent condensation. Condens water might destroy electronic parts of the ITCU.

- CAUTION! Make sure that no condensation occurs on or inside the unit.

Condensation

If you use plastic sheets or tent-like solutions, you must ensure condensation does not accumulate on or inside the unit.

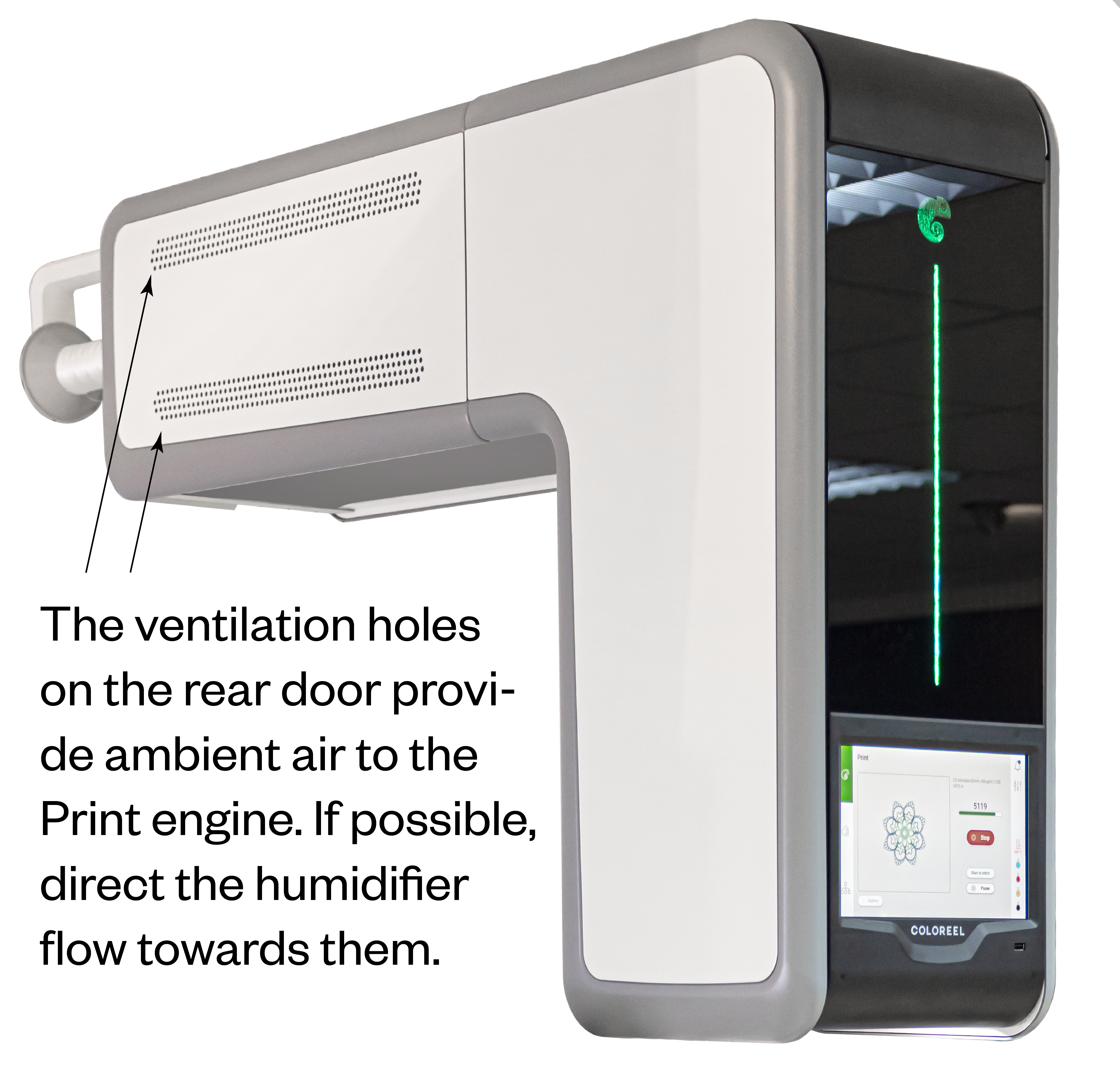

Make sure that air can circulate freely around the unit. The area on top of the unit, near the fan output, is extra sensitive.

Only use the humidifier when needed and remove plastic sheets or similar during periods when unnecessary. Condensation getting inside the unit may cause corrosion and electronic failures.

Good examples

- This photo shows an 8-head installation at a customer using textile curtains (covering the sides and the top of the stand, like a ceiling). This method is a great help in keeping the humidified air from the humidifiers surrounding the units and keeps them running within operation specifications.

-

Bad examples

- This photo shows how a customer "wrapped" the ITCU with a plastic sheet and put a humidifier beneath it. It made the humidity high enough for operation but also created condensation within the unit, causing internal electronics to be destroyed.

.jpg)

Why are there limitations of Temperature and Humidity?

To prevent the thread from becoming fragile To secure color quality, function and lifetime of the Print Engine moduleWhat happens if we run the ITCU out of specification range?

The thread color will be different You can't, the built in software will prevent you from using the ITCU The thread colors will no be at the right place in the designSubmit answers